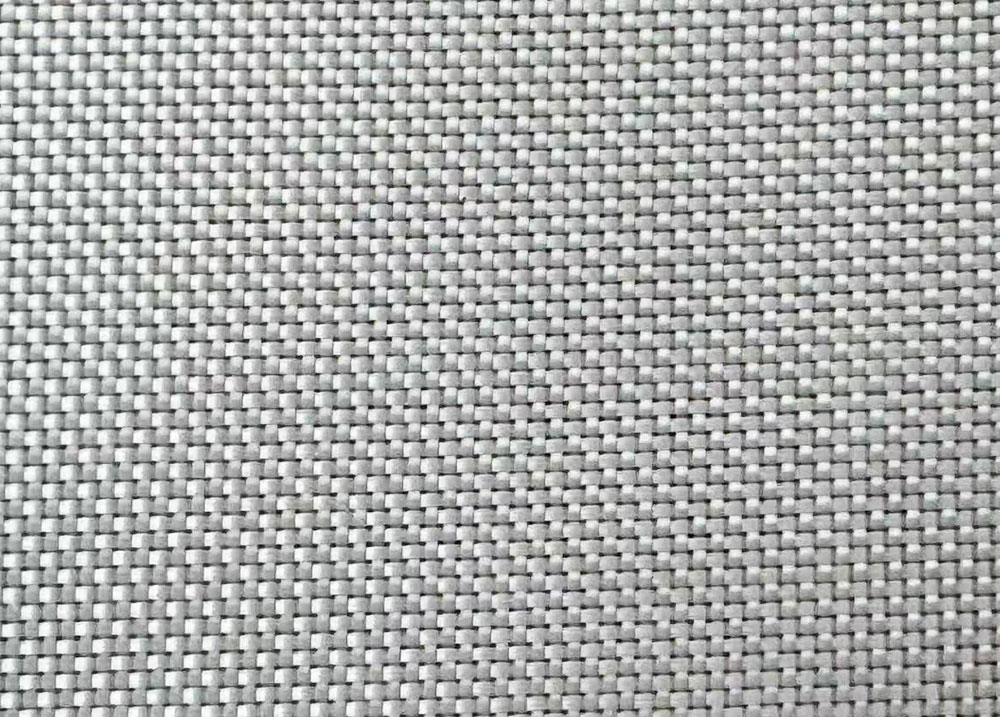

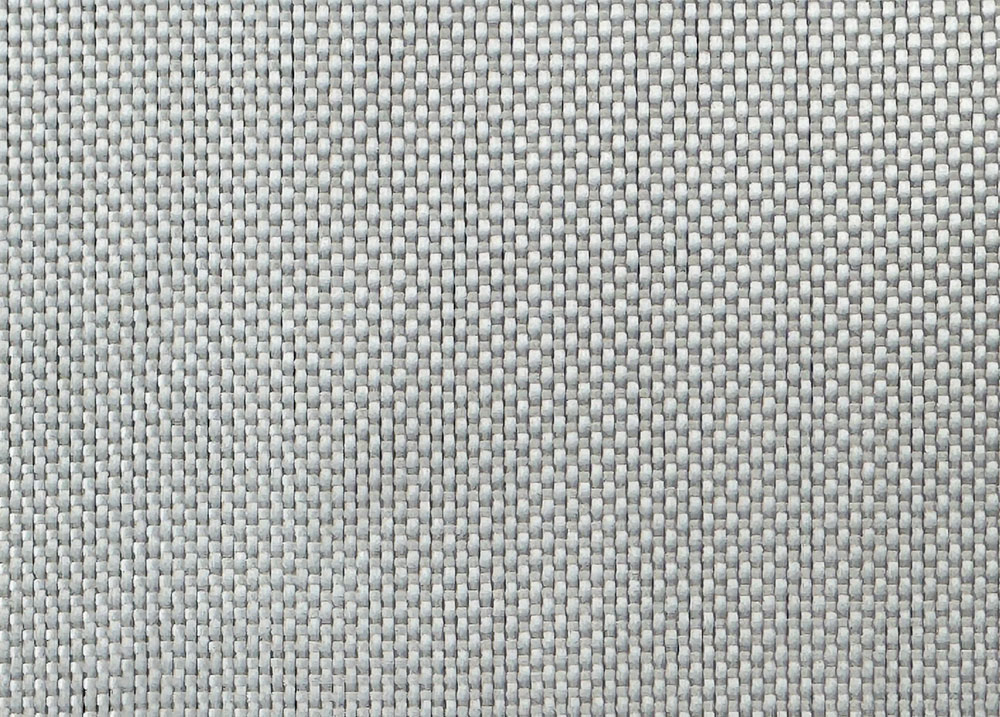

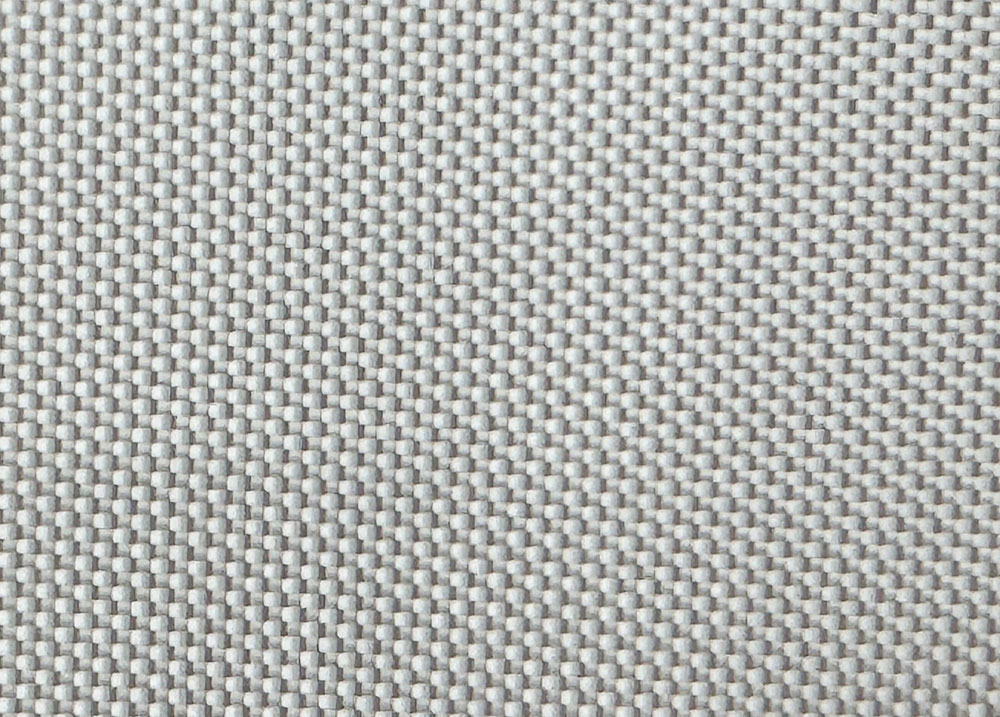

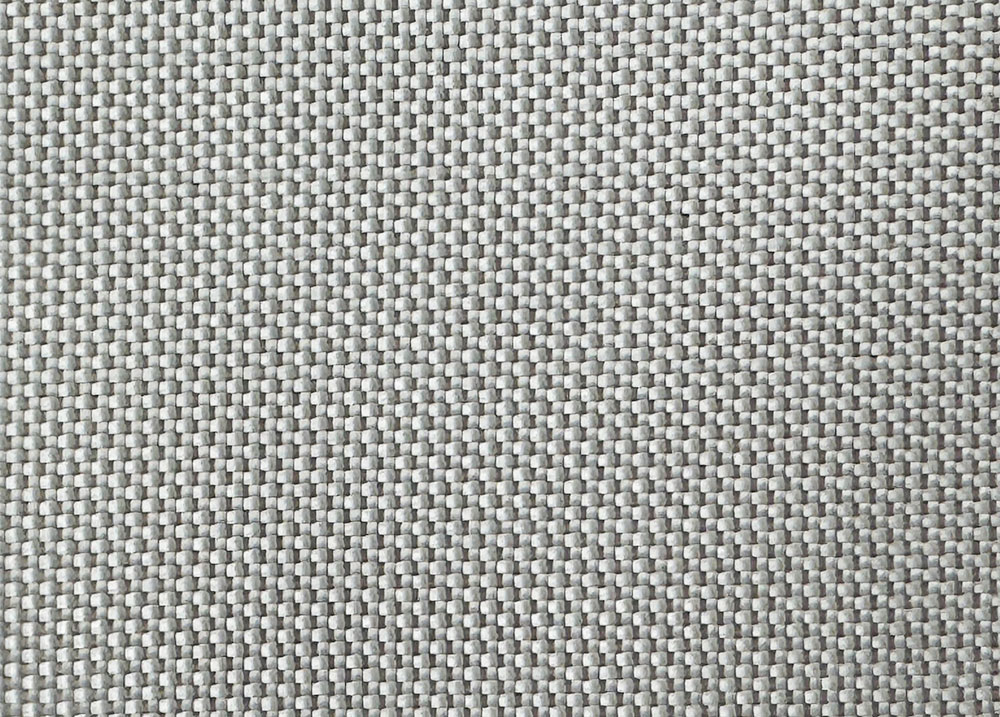

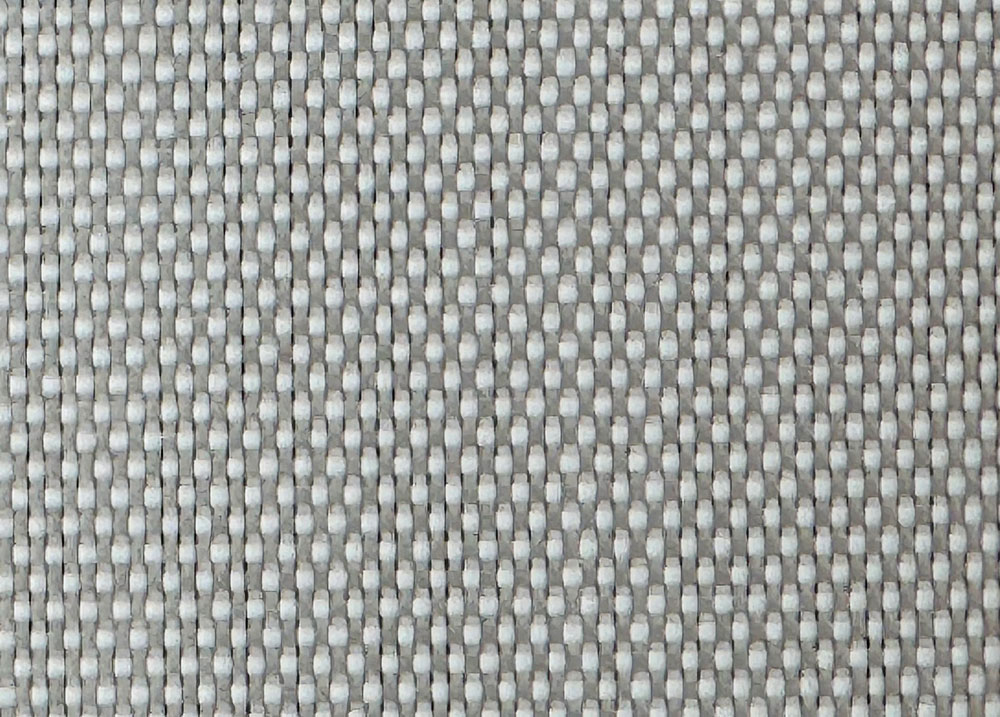

Fiberglass Woven Fabric is an industrial fabric made from glass fibers through the traditional weaving process (vertical interweaving of warp and weft yarns). Its core value lies in the fact that the inherent characteristics of glass fibers (such as high strength, high-temperature resistance, and insulating properties) are directed and enhanced through the weaving structure to become a reinforcing substrate for composite materials or a functional isolation material.

Composition

The base material is silicon dioxide (SiO₂, content 50-75%), supplemented with metal oxides such as alumina (Al₂O₃), calcium oxide (CaO), and other metal oxides, which are melt-drawn to form continuous fibers with diameters ranging from 5 to 24 microns.

Type

E-glass (general-purpose type, excellent insulation, low cost)

S-glass (high-strength type, tensile strength 30-40% higher than E-glass)

C-glass (acid-resistant type, for corrosive environments)

Weaving Technique

Yarn preparation: glass fiber raw yarns are twisted or merged to form yarns for weaving (e.g. EC9 67tex, 200-400 monofilaments).

Loom type: rapier loom (to reduce fiber damage), air jet loom (high-speed production).

Organization

Plain Weave: compact structure, mechanically isotropic, used for circuit board substrates

Twill Weave: Highly flexible, suitable for curved composites (e.g. boat hulls)

Satin Weave: smooth surface, excellent resin wettability (aerospace laminates)

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More